Manufacturing MES on the shop floor: a bogey or a bonus?

You own a small workshop. After careful calculations, you’ve made up your mind: it’s time to implement manufacturing execution software (MES). Although you have decided, you start having second thoughts after consulting your team.

Your foreman – usually a happy-go-lucky guy – is moody and grumpy. He starts talking about working too long in the same company (implicitly your company). The rest of the staff seems to be in a sour mood too. Are they going to hand in their notices once you introduce manufacturing MES? Maybe they just play a tug of war with you?

A matter of perspective

In manufacturing, money is made on the shop floor. That’s why manufacturing control software has many advantages from the manager’s point of view. For example, the graphical production schedule provides a fast visual summary of the loading of all active orders and essential information associated with individual operations, such as work order number, status, quantity and due date. Thanks to this:

- You know who’s working on the job, where in the production process it is and if you’re going to meet the delivery date,

- Prioritise the status of a job quickly by simply dragging and dropping it with your mouse, which creates a transparent and open communication channel from the shop floor to the home office.

- You can follow critical metrics for optimal performance and efficiency.

- Store your BOMs, photos, invoices and other project files online.

They are just a few pluses of an online MES; that’s why it is such a popular choice with small manufacturing companies. But, generally speaking, this production control solution makes decisions more comprehensive, accurate, and up-to-date information than ever before.

Manufacturing software gives 360-degree visibility across all aspects of business and provides actionable insights about every facet of your operation, anytime, anywhere.

Naturally, it sounds like a dream come true for the business owner, and it is an obvious bonus. But as they say, what you see depends on where you stand, which might be the opposite for a mid-level staffer. As a result, they are suspicious and don’t trust such innovations, regarding them as the boss’s folly and evil to the world. So they expect the worst of it.

Three common quandaries when it comes to manufacturing MES and how to overcome them

For small manufacturing companies, even the simplest shop floor control software enables project cost efficiency and transparency. It also preserves precious company know-how delivering significant quality and productivity improvements. At least in theory.

- Fear of efficiency tracking

The workers fear the new MES, thinking the manager will use it to track their efficiency. Once they clock in, they must fulfil the most demanding standards and expectations. What if a boss turns out to be a “slave driver”? Life would be impossible then, and the new tool will be used wrong. The vision of a foreman who only pushes staff to the limits and establishes unrealistic working schedules, calculating every second of their work, makes them freeze in their tracks. Employees usually despise such control andsee it in a negative light.

The manager’s attitude is essential: if they start complaining about every 2 seconds delay and demand impossible results, things will go awry. Everybody wants to be respected, whether labourers, blue collars or office workers.

- They feel that their voice doesn’t count.

The common problem is that an implementation decision is made “at the top without consulting staff. As a result, workers might feel excluded and no longer needed. Could their experience be less valuable? Does the company want to dispose of them? Maybe the new software system will be too complex for them to learn? Will they be fired? There are many doubts and questions about their future.

People generally don’t like changes, so complaints about introducing a new tool will occur. For example, they might say that it takes too long to click on the computer – they could use that time actually to do more work on the shop floor.

In reality, manufacturing MES is convenient for the staff more than they want to admit. Experience shows that people react very well to a new system (as long as it isn’t a complicated ERP). When everything is clear and easy to understand, like in Prodio, workers themselves complement the software. From their perspective, it offers more order and transparency. When somebody comes to work in the morning, they can see which tasks they were assigned and which ones are due first and start working following the priority of things in the queue. There is no need to wait for the boss who runs frantically from machine to machine, suggesting last-minute changes and giving contrary orders resulting in confusion and disorder. In the end, an employee takes the blame for all mistakes, does not pay attention, and lazes around. Simple manufacturing production software ensures such situations are impossible because everything works round the clock and is in proper order.

- MES will be too difficult to learn

The new MES will be too hard to use – you can hear it on the grapevine, even before the workers see the tool. Unfortunately, not everybody is keen to learn – as the common proverb says: you can’t teach an old dog new tricks. Some staff might deliberately make your life difficult because they simply don’t want changes. Another stereotype is that unskilled people work on the shop floor, and anything sophisticated won’t pass. They would instead look for a new job than learn.

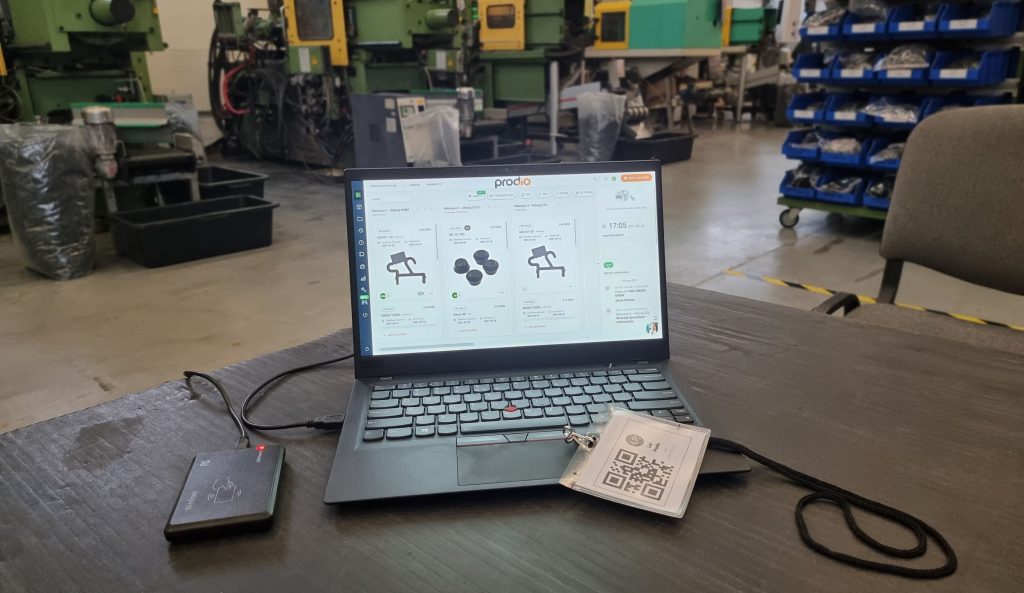

Some ERP systems are complicated, but this is not the case with Prodio. It is as easy as sending a text message or logging into your email account. In one of the companies where Prodio was inroduced, even an 80-year-old foreman learnt to use it, saying that it is a piece of cake”.

There are just some of the most prevalent dilemmas mentioned above. Many manufacturing company owners put off the implementation of MES software for fear of workers’ protests. They cover up the stalling by making different excuses, usually financial ex. “we can’t afford it,” “it’s going to cost us a penny”, or “it’s not the right time”.

Benefits of MES for shop floor workers

Many years of manufacturing experience proved that fear doubles all because production software can be a great tool to motivate the whole team. Most people want to do a good job, to prove themselves. Of course, there are always exceptions, but apart from fulfilling basic needs (financial, psychological, social), the daily grind gives us a sense of purpose and satisfaction.

Thanks to a proper system, it is much easier to see the effort put into work. Therefore the norms are not only a method of efficiency tracking but also a valuable negotiation point for a salary level or a monthly bonus. When you do your job well, there is no need to be scared of assessment because there is nothing to hide. Moreover, no one can blame their mistakes on you because it is all in the system: names, dates, time, quantity and quality.

Workers on the production floor still rely on pen and paper, and spreadsheets to manage production records have a much more complicated task because these manual activities are prone to error. Using digitalised manufacturing records, such as in Prodio, makes it transparent who’s responsible for each job. When the mistake happens, you can check the working history and see who’s a fault it was: the worker, the manager or maybe the contractor?

Another advantage of the manufacturing execution system is building a company culture focused on finding solutions rather than pointing the finger at somebody. Faults and complaints are a natural part of the manufacturing process; once they occur, the company can learn from them. In addition, the communication between managers and employees doesn’t have to be messy or complicated. Prodio ensures that everyone in your company is on the same page, no matter where they are. You can share critical messages, documents and photographs of potential defects or ready-made goods. It is much easier to avoid mistakes when a picture or photo is attached to the task, with a note showing possible hurdles. These are visible straight away on the production schedule, so the moment you are assigned the task, you get the whole package: method, BOM, photos and comments. The progress is indicated but coloured status buttons; when you are stuck, you can leave a comment (also visible across the shifts). Why is it so important? There is less sweeping under the carpet. Problems are cleared on the spot because you get early indications of potential issues, so you can take corrective action immediately.

Manufacturing MES means a transparent division of responsibilities. Assigning tasks to your operators based on the production schedule means they don’t have to waste time waiting to be told in person what to do. Once they clock in at the beginning of their shift, their workload for the day is visible. That means less pressure: the manager sees the real-time work-in-progress, so there is no need for questions: “have you finished?”, “what’s next?”, “Are we done here?”

Stop analysing and start using MES.

Will your software be a stick, and a carrot solution depends solely on you? Employees will always be afraid of changes because it is human nature. Those with something to hide the loudest complaint, as they are scared their “sloppy work” will see the daylight, and that will be it. They are right to be afraid: the faster you implement MES, the quicker you discover botched jobs. Don’t wait for the 100% support of your shop floor crew – you might be waiting forever. A simple MES, such as Prodio, is a cloud-based solution for rapid deployment (less than 15 minutes) with no up-front costs. Straight away, you get access to all functions and test the program. It doesn’t sound like a bogey, does it? 😉